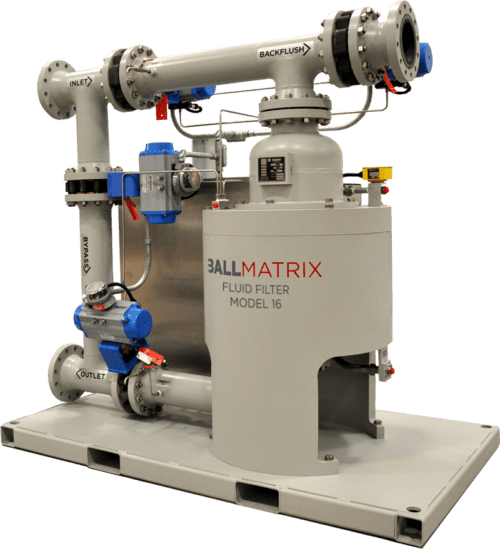

Simple, Effective Electromagnetic Fluid Filtration

BallMatrix's Applications for E-Coat Process Fluid Filtration

Metal fabrication and welding within manufacturing facilities produce various metal particles like weld balls and metal fines that contaminate process fluids in both the Pretreat and E-coat stages of an E-coat application system. If not removed, these ferrous particles can cause aesthetic paint defects that require manpower, materials, and time to correct; all of which mean higher expense.

Multilevel filtration methods such as bag filters, cartridges, strainers, hydrocyclones, and rare earth (permanent) magnets are commonly used to remove these ferrous contaminants. These methods often fail to remove the micron size metal particles that ultimately cause the defects. The Milhous Company BallMatrix Electromagnetic Iron Separator System is designed with a ferritic packed bed matrix that specifically targets those micron size iron particles. Unlike other filtration methods, the BallMatrix is a fully automated system that requires zero filter bed maintenance.

Applications of BallMatrix for E-Coat and Paint Process Filtering

BallMatrix is incorporated into the e-coating process to filter magnetic contaminants out of the process fluid, resulting in quicker output and fewer defects. E-coat is a favorite of the manufacturing industry for several reasons:

- Eco-Friendly: It emits no hazardous air pollutants or volatile organic compounds. It complies with OSHA and EPA regulations.

- Efficient. E-Coating immerses components in the solution, making it more effective than spray painting and suitable for greater volume production runs with minimal waste.

- Compatible. Because of its capacity to produce excellent inter-coat adhesion with most topcoats, this technique may be employed as a primer for virtually all magnetic applications.

- Durable. E-coating is well-known for its chip resistance and ability to withstand external weather conditions and indoor settings where caustic chemicals are present.

BallMatrix enables manufacturers to effectively manage e-coat process fluid with process contamination and achieve the benefits listed above while maintaining cost-effectiveness and a low defect rate. Some industries our filtering process can serve include:

- Commercial Vehicles and Industrial Non-Commercial Vehicles

- Fire Equipment: E-coat protects equipment from chemicals, corrosion, wear, and surface scratches.

- Marine: This coating shields submerged objects and boats, ships, and yachts from saltwater, bacteria growth and corrosion.

- Military: E-coat protects military equipment such as vehicles, frame rails, rims, and body panels. E-coating provides corrosion resistance, edge coverage, and protective throw power, making it an excellent choice for military vehicles and equipment.

Pretreatment/E-Coat Filtration With BallMatrix

Pretreatment and E-coat process fluids are often contaminated with weld balls and other magnetic particles from the manufacturing processes. Filtering out these magnetic contaminants can often be tricky, costly, dangerous, and time intensive. However, our BallMatrix Electromagnetic Iron Separator System removes the defect causing iron particles upfront, protects the quality of your treatment materials, helps maximize production with its fully automated backwash system, and effectively removes iron particle contaminants that would otherwise interfere with operations and the final product. The BallMatrix can quickly filter up to 2,400 GPM of Pretreatment and E-coat process fluids at an impressive filtration efficiency of 99%.

BallMatrix Design Standards

Every BallMatrix filtration system is designed to meet or exceed standards established by:

- ASME (American Society of Mechanical Engineers)

- ANSI (American National Standards Institute)

- ASTM (American Society for Testing and Materials)

- NEMA (National Electrical Manufacturers Association)

About BallMatrix

The Milhous Company “Maintenance Free” BallMatrix Electromagnetic Iron Separator System was originally developed for use in nuclear power generation facilities, which have rigorous requirements for continuous, maintenance free operation. The BallMatrix is the only electromagnetic filter (EMF) design to offer a truly permanent matrix and consistent efficiency for the life of the equipment. Because of the unique ability of this matrix to be thoroughly cleaned each time the filter is flushed, you will never have to replace the matrix, nor will you ever have to resort to chemical cleaning to restore filtration efficiency.

Since electric power is the only “consumable” associated with operation of the BallMatrix, a great deal of effort has been expended to design and build equipment that will demand a minimum of power. The result of these efforts is an EMF that typically uses a third of the power required by the same size equipment of other designs. When power requirements, over the 40-year design life objective of the filter are considered, the BallMatrix has an overwhelming cost advantage over competing designs.

Some key benefits of using a BallMatrix filtration system include:

- 99% removal rate of magnetic contaminants

- Reduced costs for operation: no filter bed/matrix replacement costs, automated backwash cycle means no disruptive filter bed maintenance required and minimal downtime

- Reduced defects on electrocoated surface: reduced labor costs to manually fix surface defects from magnetic material contamination in the E-coat process (compromised surface/corrosive risk and visual defects)

- Increased lifespan of equipment because of the removal of magnetic contaminants, which can extend system and equipment lifespan

How BallMatrix Filtration Works

How BallMatrix Filtration Works

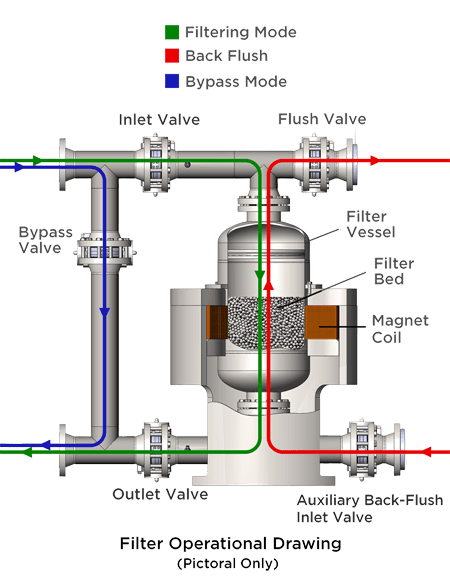

There are three main phases of operation in the BallMatrix filtration system.

- First, the electromagnetic filter bed — which is composed of magnetically susceptible spherical components — is energized by a magnet coil, producing a magnetic field around the bed, and smaller, more powerful localized fields, around each sphere.

- Next, the process fluid is directed through the bed, which captures and contains magnetic contaminants at a 99%+ filtration efficiency rate.

- Once the bed is loaded with magnetic contaminants, the automated backwash is activated, and magnetic contaminants are automatically flushed away requiring no equipment replacement or personnel interaction.

From start to finish, the entire backwash process takes a mere two minutes.

Turn to Milhous Company for Superior Electromagnetic Filtration Systems and Services

Milhous Company has been a leading provider of magnet systems for over 45 years. Milhous specializes in designing and building high-performance electromagnetic fluid filtration solutions for industrial processing centers, automotive manufacturers, and more. The BallMatrix Electromagnetic Iron Separator System is a top-tier filtration solution that guarantees excellent filtration performance and long-lasting capabilities. If you need to address suspended magnetic material in your facility’s fluid streams, the BallMatrix Electromagnetic Iron Separator System can give you complete filtration capabilities with maximum performance and efficiency.

Contact us today to learn more about our abilities and how our talented team can assist your organization with iron particle removal.