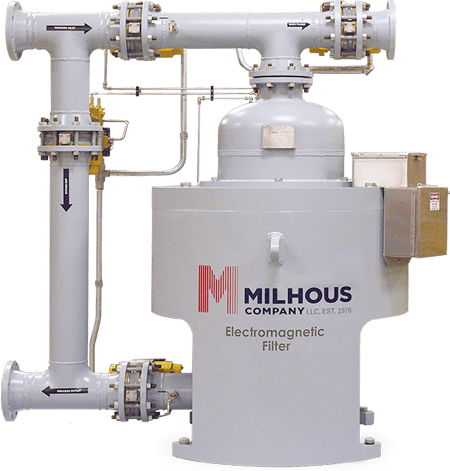

Simple, Effective Electromagnetic Fluid Filtration

CAPABILITIES

The Milhous Company BallMatrix® Electromagnetic Fluid Filtration System has a long history of service in the industrial, power generation, laboratory, and commercial markets to some of the largest and most prestigious companies in the world. From project inception to operation, Milhous works with clients to deliver a filtration solution that achieves a cleaner process stream while reducing operating and energy expenses.

The BallMatrix filter removes more than 99% of suspended magnetic contaminates as well as concentrations of paramagnetic materials and other magnetically susceptible solids. Designed for automatic operation, the BallMatrix self-cleaning filter bed will never require replacement or maintenance. Additionally, the low power consumption required to operate the BallMatrix and its 40-year design life make the BallMatrix a viable asset to reducing operating expenses to whatever industry it is applied.

All system components of the BallMatrix are professionally manufactured from the finest quality raw materials. Built to ASME, NEMA, ANSI, and ASTM standards, they hold both CE and TUV approvals. With our advanced manufacturing facility, multi-disciplined staff and decades of experience, Milhous has the resources to successfully meet the most stringent specifications.

Contact Us today to learn more about the BallMatrix Electromagnetic Fluid Filter System.

Technology specifications

- General Capabilities

Electromagnetic Fluid Filtration Systems

- Applications

Boiler Systems, Paint Systems

Fluid Process Streams (All Fluids)

- Benefits

Increase Efficiency of Process System

Lower Energy Costs

Decreases Maintenance

Power Efficient in Operations

No Maintenance Required on Filter Bed- Self-cleaning Bed

- No replacement of Bed Media

- 40 Year Life Design

Low Power Consumptions (Max 30 amps)

Very Large Flow Capacity

Automatic Operation

98%+ Efficient

- Filtration Performance

Removes 95% of:

- Suspended magnetic contaminates

- Iron Oxide (Fe304 / magnetite)

- 90% of total iron

Paramagnetic Materials

(It has to have a certain percentage of magnetic

particles for it to be attracted and removed)- Copper

- Nickel

- Cobalt

- Other Magnetically Susceptible Solids

Reduces:

- Iron Fouling of Resin Beds

- Cost of Chemical Cleaning

- Cartridge Filtration Use

- Manual Waste Disposal

Additional information

- Industry Focus

Nuclear Power

Laboratory

Commercial

Automotive

Oil & Gas

Public Water Systems

Manufacturing

High Purity Water

Metallurgical

Food Industry

Beverage Industry

- Industry Standards

ASME

ANSI

ASTM

CE

NEMA

TUV

ISO 9001:2015 (Compliant)

National Electric Code