Magnetic Filtration 101

Filtration removes contaminants, such as microbes, inorganic solids, and minerals, from fluid streams. It is essential for many applications that require high-purity fluid to achieve and maintain safe, consistent, and/or efficient operations. One of the most popular methods of filtering ferrous particles from fluids is magnetic filtration, which uses a magnetic core or rod to attract and collect ferrous compounds from a fluid flowing around it.

The following blog post provides an overview of magnetic filtration. It highlights how magnet filters work, their main advantages, the types available, and the industries served. Additionally, it covers the solutions offered by Milhous Company, a premier provider of electromagnetic iron filtration systems.

Magnetic Filtration 101: How It Works and Main Advantages

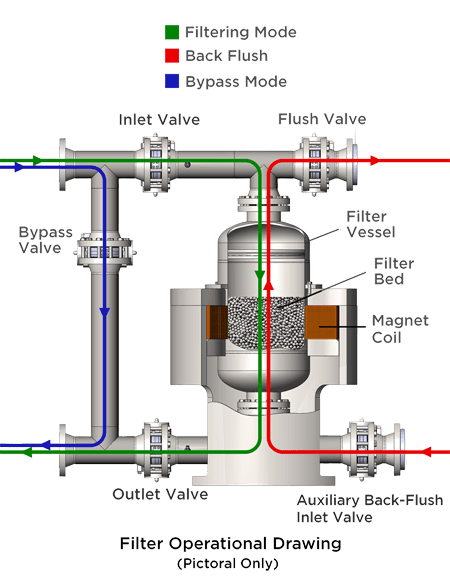

Magnetic filtration systems use either neodymium rare earth magnets, also known as permanent magnets, or electromagnetic coils to collect and remove ferrous particles within a fluid stream. The particles may come from contamination caused by a previous processing stage or from equipment breaking down. The magnets generate a magnetic field that attracts the magnetically susceptible particles from the fluid stream and captures them in a magnetized matrix. After the filtration process is completed, the filter matrix can be removed to wash away the captured particles and then replaced in the system to be reused.

Magnetic filters are superior to cartridge, bag, and/or screen type barrier filters. Barrier filters collect contaminants within a limited size range. The filter bed matrix for these types of filters must be sized perfectly. If the filter matrix is sized too small for the particle size being removed, the filter matrix will become easily clogged, reducing the flow through the filter. Operation under this condition ultimately leads to pressure buildup that causes contaminant breakthrough. Conversely, magnetic filters can generally remove most ferrous contaminants, regardless of their size.

Compared to other filters, magnetic filters also offer the following advantages:

- They are less expensive to maintain and operate since they can be cleaned and reused.

- They usually require less maintenance due to the ability to have automated cleaning systems.

- They are more effective and environmentally friendly since the contaminants they collect can be recycled, and the fluids they filter retain their characteristics.

Permanent Magnet vs. Electromagnetic Filtration

Magnetic liquid filtration systems can be classified into two main categories: permanent magnet filters and electromagnetic filters.

Permanent Magnet Filtration Systems

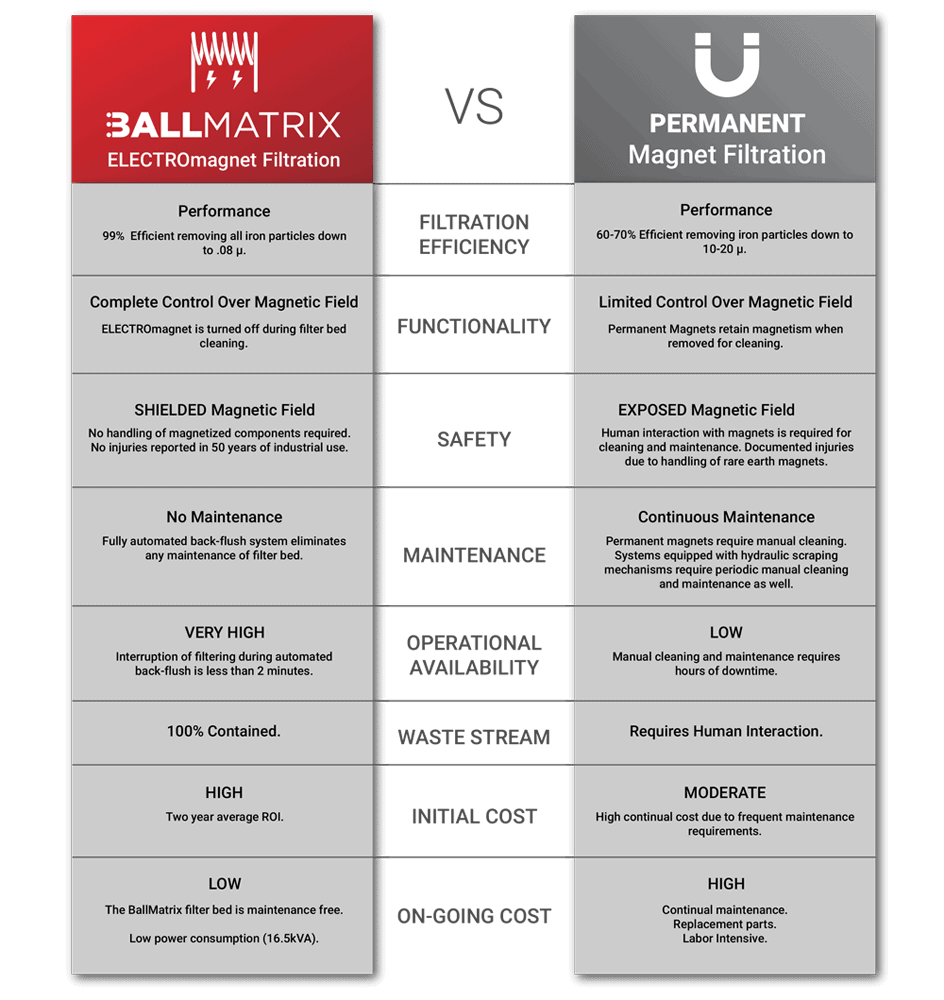

Permanent magnets have molecules that are permanently oriented to generate a magnetic field. They can be made from various materials, such as neodymium, samarium-cobalt, alnico, and ceramics, that are given a permanent magnetic charge during the manufacturing process. As a result, they have a strong, long-lasting charge, making them a good choice for simple, larger particle filtration systems.

Electromagnetic Filtration Systems — BallMatrix®

Electromagnets are not permanently fixed to generate a magnetic field. Instead, they generate a magnetic field when an electrical current is applied. This quality allows operators to control when the electromagnetic is on and off.

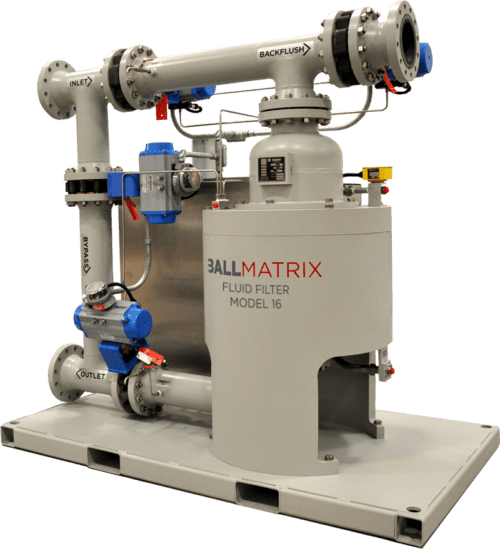

Milhous Company’s BallMatrix® electromagnetic filtration systems are the most simple and effective liquid filtration solutions for iron available in the market. They offer numerous advantages over permanent magnet filtration systems. For example:

- They allow for complete control over the magnetic field, ensuring safe operation and maintenance.

- They achieve 99% filtration efficiency with no minimum or maximum flow requirements.

- They have an automated two-minute backwash system that requires no personnel interaction.

- They are virtually maintenance-free due to their required 40-year design life.

- They have 100% contained waste streams.

Benefits of BallMatrix Electromagnetic Fluid Filtration Systems

Some of the key benefits of BallMatrix filters include:

- Increased fluid process efficiency — No matter the liquid, particle size, or flow rate, the BallMatrix removes 99% of micron and submicron iron particles from process fluids.

- Enhanced operational efficiency — The virtually maintenance-free BallMatrix helps reduce downtime and increase production.

- Decreased maintenance costs — The electromagnetic filter matrix is permanent and will never have to be manually cleaned or replaced.

- Reduced energy costs — The amount of energy required to power the BallMatrix is only 16.5 kVA.

Industries Served

Magnetic filtration systems find application in many industries, including, but not limited to, the following:

- Automotive

- Power Generation

- Pulp and Paper

- Food and Beverage

- High-Purity Water

- Manufacturing

- Metallurgy

- Nuclear Power

- Oil and Gas

- Public Water

Contact Milhous Company for Superior Magnetic Iron Filtration From Liquids

If you’re looking for an electromagnetic fluid filtration system you can count on in your most critical operations, turn to the electromagnet experts at Milhous Company. Our iron separation filter systems are built in compliance with numerous industry specifications and standards, including National Electric Code, ASME, ASTM, ANSI, CE, TUV, and NEMA. Additionally, our ISO 9001:2015 certified quality management program ensures the quality of our solutions.

To learn more about our electromagnetic filtration solutions and how they can benefit you, contact us today. To get started on your solution, request a quote.