Electromagnetic Filtration in the Oil Reclamation Process

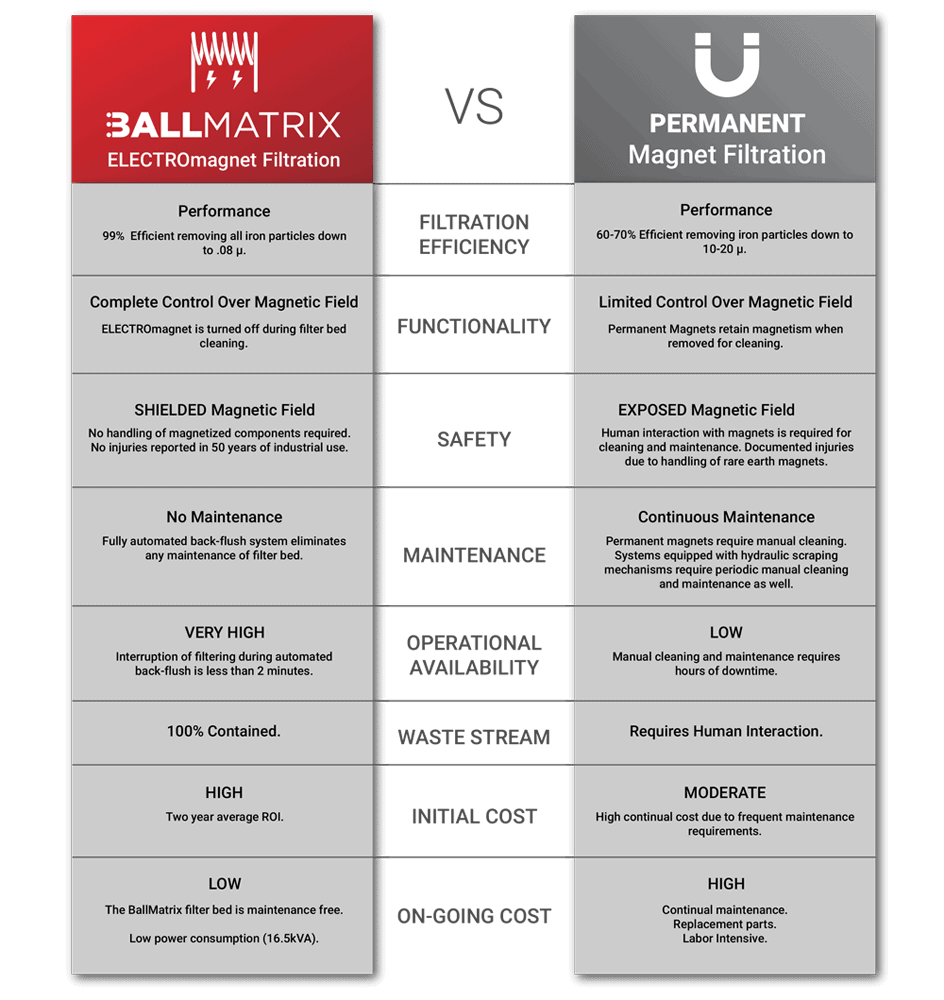

Leave a CommentMagnetic filtration systems come in two essential varieties: a permanent magnet system that uses a permanent or rare earth magnet to remove metal particles from reclaimed oil, or an electromagnetic system, which can hold an electrically generated magnetic field at optimal times and intensities. Permanent magnetics have relatively low filtration efficiency, leaving behind approximately 30-40% of iron particles in the oil. It also requires continuous manual effort for operation and maintenance while simultaneously posing a danger to human operators because of its constant magnetic field.

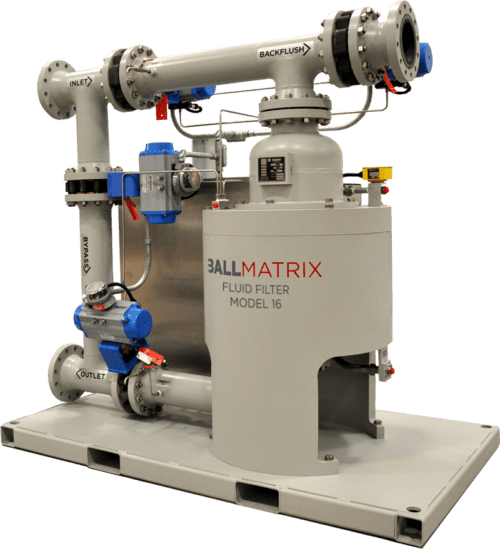

Our BallMatrix electromagnets, on the other hand, offer a 99% efficiency rate, give operators complete control over the magnetic field for efficient operations and safety, and reduce downtown during scheduled maintenance compared to a permanent magnet system. Take a closer look at the role of electromagnets in the oil reclamation process, the benefits of choosing electromagnets, and how to build the right filtration system for your business.

Usage of Electromagnets in the Reclaiming Oil Process

Oil can degrade over time or during processing, becoming contaminated with organic matter, minerals, and traces of metal. Submicron iron particles, in particular, pose a significant challenge in reclaiming oil. However, electromagnetic systems can target those iron particles as part of the reclaiming process.

The first stage of the oil reclamation process involves mechanical filtration to remove large organic and metal particles. To remove iron particles greater than 50 microns in size, systems often use permanent magnets and other traditional filtration methods; these methods can handle the removal of larger iron particles with a high degree of consistency.

However, smaller particles — those below 50 microns or at the sub-micron level — require finer and more accurate tools for reliable filtration. During the second stage of the oil reclamation process, operators need a filtration process that can remove iron particles as small as <1 microns. If the iron isn't filtered from the oil, it can oxidize and contaminate the fluid. Iron particles also attach to vessels used throughout the heating and refining process, leading to damage and additional costs. Our BallMatrix electromagnet generates hundreds or even thousands of electromagnetic fields to capture submicron iron particles, leading to a 99% removal rate that makes the oil easier to refine and reclaim.

Benefits of Electromagnetic Filtration for Oil Reclamation

Filtering contaminants out of reclaimed oil is essential to protect the integrity of the product and the systems used to refine it. While permanent magnets (and traditional filtration methods) can handle the initial stage of removing large particles, an electromagnet is a more effective choice. Electromagnets also outperform mechanical filtration systems like grid filters and cartridge filters. Some of the key benefits of our Iron Separator System are:

- Higher Revenue: Highly filtered oil is a better product, and it performs better on the market. By fully filtering your oil to remove small and large iron particles, you can sell your oil for a higher price and generate more revenue per unit.

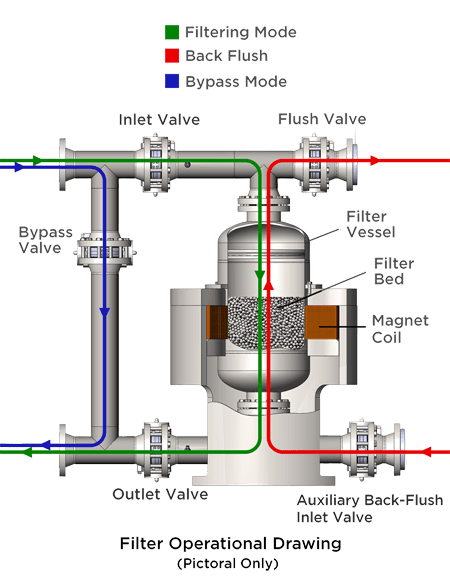

- Faster Processing: Permanent magnets need a lot of manual maintenance and attention. Our BallMatrix system takes those maintenance tasks off your team’s to-do list. It doesn’t need to be hand cleaned or cleaned by hydraulic wipers, due to the automatic backwash system. When the filtration system turns to automatic backflush mode, the magnetic field is shut off in order for the debris to cycle out of the system. There is no personnel interaction or manpower required, and the filtration system can be up and running again as soon as the system is clear. Not only does this ensure faster and more consistent industrial oil filtering without downtime, but it also reduces the cost of labor.

- Excellent Results: Our BallMatrix electromagnet removes 99% of iron particles or more. It outperforms both permanent and rare earth magnets and rare earth magnets by generating hundreds or thousands of magnetic fields that the particles can’t evade.

Design Your Electromagnetic Filtration System With Milhous

Reliable electromagnetic oil filtration solutions help you filter oil so you can deliver a better product at a higher price. At Milhous, we design electromagnetic fluid filtration systems that are designed to capture submicron particles without the maintenance and operational costs of other magnetic filtration systems. Contact us today to learn more about our BallMatrix solution.